- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Flat LED Lighting

- Flat LED Lighting

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Sturdy Interlock Switches

- Sturdy Interlock Switches

- Smart Circuit Design

- Smart Circuit Design

- Smart Relays

- Smart Relays

- Solutions

- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Flat LED Lighting

- Flat LED Lighting

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Sturdy Interlock Switches

- Sturdy Interlock Switches

- Smart Circuit Design

- Smart Circuit Design

- Smart Relays

- Smart Relays

-

Solutions

- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Flat LED Lighting

- Flat LED Lighting

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Sturdy Interlock Switches

- Sturdy Interlock Switches

- Smart Circuit Design

- Smart Circuit Design

- Smart Relays

- Smart Relays

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Production Line Safety

- Production Line Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Smart Maintenance Safety

- Smart Maintenance Safety

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

- Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Production Line Safety

- Production Line Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Smart Maintenance Safety

- Smart Maintenance Safety

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

-

Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Production Line Safety

- Production Line Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Smart Maintenance Safety

- Smart Maintenance Safety

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

- Waterproof Switches

- Waterproof Switches

- Traceable Systems

- Traceable Systems

- Remote Monitoring

- Remote Monitoring

- Small Display Devices

- Small Display Devices

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Controllers

- Smart Controllers

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Affordable Robots

- Affordable Robots

- Smart Emergency Stop

- Smart Emergency Stop

- Smart Static Elimination

- Smart Static Elimination

- Solutions

- Waterproof Switches

- Waterproof Switches

- Traceable Systems

- Traceable Systems

- Remote Monitoring

- Remote Monitoring

- Small Display Devices

- Small Display Devices

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Controllers

- Smart Controllers

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Affordable Robots

- Affordable Robots

- Smart Emergency Stop

- Smart Emergency Stop

- Smart Static Elimination

- Smart Static Elimination

-

Solutions

- Waterproof Switches

- Waterproof Switches

- Traceable Systems

- Traceable Systems

- Remote Monitoring

- Remote Monitoring

- Small Display Devices

- Small Display Devices

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Controllers

- Smart Controllers

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Affordable Robots

- Affordable Robots

- Smart Emergency Stop

- Smart Emergency Stop

- Smart Static Elimination

- Smart Static Elimination

- Intrinsic Measures

- Intrinsic Measures

- Traceable Systems

- Traceable Systems

- Easy Traceability

- Easy Traceability

- Compact Equipment

- Compact Equipment

- Code Readers

- Code Readers

- Easy Switch Replacements

- Easy Switch Replacements

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Compact Safety Door Switches

- Compact Safety Door Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

- Solutions

- Intrinsic Measures

- Intrinsic Measures

- Traceable Systems

- Traceable Systems

- Easy Traceability

- Easy Traceability

- Compact Equipment

- Compact Equipment

- Code Readers

- Code Readers

- Easy Switch Replacements

- Easy Switch Replacements

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Compact Safety Door Switches

- Compact Safety Door Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

-

Solutions

- Intrinsic Measures

- Intrinsic Measures

- Traceable Systems

- Traceable Systems

- Easy Traceability

- Easy Traceability

- Compact Equipment

- Compact Equipment

- Code Readers

- Code Readers

- Easy Switch Replacements

- Easy Switch Replacements

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Compact Safety Door Switches

- Compact Safety Door Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

- Machine Tools

- Solutions

- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Flat LED Lighting

- Flat LED Lighting

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Sturdy Interlock Switches

- Sturdy Interlock Switches

- Smart Circuit Design

- Smart Circuit Design

- Smart Relays

- Smart Relays

-

Solutions

- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Flat LED Lighting

- Flat LED Lighting

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Sturdy Interlock Switches

- Sturdy Interlock Switches

- Smart Circuit Design

- Smart Circuit Design

- Smart Relays

- Smart Relays

-

Machine Tools

- Solutions

- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Flat LED Lighting

- Flat LED Lighting

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Sturdy Interlock Switches

- Sturdy Interlock Switches

- Smart Circuit Design

- Smart Circuit Design

- Smart Relays

- Smart Relays

-

Solutions

- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Flat LED Lighting

- Flat LED Lighting

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Sturdy Interlock Switches

- Sturdy Interlock Switches

- Smart Circuit Design

- Smart Circuit Design

- Smart Relays

- Smart Relays

- Robotics

- Solutions

- Robot Safety Sensors

- Robot Safety Sensors

- Robot Safety Switches

- Robot Safety Switches

- Robot Warning System

- Robot Warning System

- Solutions

- Robotics

- Material Handling

- Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Production Line Safety

- Production Line Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Smart Maintenance Safety

- Smart Maintenance Safety

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

-

Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Production Line Safety

- Production Line Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Smart Maintenance Safety

- Smart Maintenance Safety

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

-

Material Handling

- Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Production Line Safety

- Production Line Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Smart Maintenance Safety

- Smart Maintenance Safety

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

-

Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Production Line Safety

- Production Line Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Smart Maintenance Safety

- Smart Maintenance Safety

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

- Food and Packaging

- Solutions

- Waterproof Switches

- Waterproof Switches

- Traceable Systems

- Traceable Systems

- Remote Monitoring

- Remote Monitoring

- Small Display Devices

- Small Display Devices

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Controllers

- Smart Controllers

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Affordable Robots

- Affordable Robots

- Smart Emergency Stop

- Smart Emergency Stop

- Smart Static Elimination

- Smart Static Elimination

-

Solutions

- Waterproof Switches

- Waterproof Switches

- Traceable Systems

- Traceable Systems

- Remote Monitoring

- Remote Monitoring

- Small Display Devices

- Small Display Devices

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Controllers

- Smart Controllers

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Affordable Robots

- Affordable Robots

- Smart Emergency Stop

- Smart Emergency Stop

- Smart Static Elimination

- Smart Static Elimination

-

Food and Packaging

- Solutions

- Waterproof Switches

- Waterproof Switches

- Traceable Systems

- Traceable Systems

- Remote Monitoring

- Remote Monitoring

- Small Display Devices

- Small Display Devices

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Controllers

- Smart Controllers

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Affordable Robots

- Affordable Robots

- Smart Emergency Stop

- Smart Emergency Stop

- Smart Static Elimination

- Smart Static Elimination

-

Solutions

- Waterproof Switches

- Waterproof Switches

- Traceable Systems

- Traceable Systems

- Remote Monitoring

- Remote Monitoring

- Small Display Devices

- Small Display Devices

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Controllers

- Smart Controllers

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Affordable Robots

- Affordable Robots

- Smart Emergency Stop

- Smart Emergency Stop

- Smart Static Elimination

- Smart Static Elimination

- Semiconductor

- Solutions

- Intrinsic Measures

- Intrinsic Measures

- Traceable Systems

- Traceable Systems

- Easy Traceability

- Easy Traceability

- Compact Equipment

- Compact Equipment

- Code Readers

- Code Readers

- Easy Switch Replacements

- Easy Switch Replacements

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Compact Safety Door Switches

- Compact Safety Door Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

-

Solutions

- Intrinsic Measures

- Intrinsic Measures

- Traceable Systems

- Traceable Systems

- Easy Traceability

- Easy Traceability

- Compact Equipment

- Compact Equipment

- Code Readers

- Code Readers

- Easy Switch Replacements

- Easy Switch Replacements

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Compact Safety Door Switches

- Compact Safety Door Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

-

Semiconductor

- Solutions

- Intrinsic Measures

- Intrinsic Measures

- Traceable Systems

- Traceable Systems

- Easy Traceability

- Easy Traceability

- Compact Equipment

- Compact Equipment

- Code Readers

- Code Readers

- Easy Switch Replacements

- Easy Switch Replacements

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Compact Safety Door Switches

- Compact Safety Door Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

-

Solutions

- Intrinsic Measures

- Intrinsic Measures

- Traceable Systems

- Traceable Systems

- Easy Traceability

- Easy Traceability

- Compact Equipment

- Compact Equipment

- Code Readers

- Code Readers

- Easy Switch Replacements

- Easy Switch Replacements

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Compact Safety Door Switches

- Compact Safety Door Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

- Special Vehicles

- Solutions

- Illuminated Switches

- Illuminated Switches

- Construction Site Safety

- Construction Site Safety

- LED Pilot Light

- LED Pilot Light

- Rugged Switch

- Rugged Switch

- Auto Machinery

- Auto Machinery

- No-Contact Controllers

- No-Contact Controllers

- Solutions

- Special Vehicles

- Automation of intralogistics

- Automation of intralogistics

Smart Static Elimination | EMEA

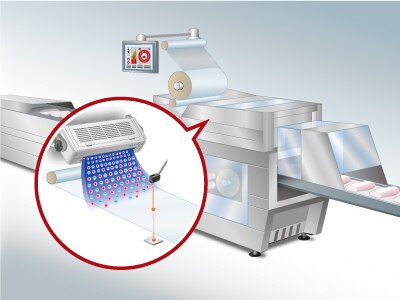

Prevent errors of packaging machinery before they occur

Improve productivity of packaging processes by eliminating static electricity

Static electricity generated by friction of packaging materials is a cause of errors

In food processing plants, the process in which products are wrapped using packaging materials is one where some problem can easily occur. One problem is static electricity being generated by the friction created from the very common practice of packaging products by pulling out roll-type packaging material to wrap the products, which then causes the packaging material to fold over and cling to itself, or the wrapping film to be drawn into the product being wrapped itself while being wrapped, as well as other problems such as the wrapped product being caught between the adhesive parts of the film, or dust getting inside the packaging. Since these problems result in downtime, and increased labor time and costs associated with redoing the packaging, food processing plants are ultimately increasing the maintenance frequency of their packaging machinery to prevent variations in packaging quality. However, it is difficult to completely prevent static electricity with these types of temporary measures, such that most cases require a fundamental solution to the problem of static electricity.

Eliminate a cause of errors by equipping with anti-static device

What is the best way to prevent packaging defects caused by static electricity? IDEC, where we are always providing measures that improve productivity and reduce costs of production lines, recommends use of our "Anti-Static Solutions". Use of our SC1P Low-Maintenance High-Speed Anti-Static Blower will prevent defects caused by static electricity such as film clinging by rapidly eliminating the static charge with emitted ions. Additionally, this compact device with an optional anti-dust filter can also be used for production lines requiring a clean environment such as in food processing plants. Although you may doubt whether an anti-static blower can be used for the special environment and applications of a food processing plant, the various merits of this product, including a width of approximately 30 cm to provide useful space savings inside packaging machinery, and for nearby equipment and static removers, a structure that prevents filter clogging, and its low maintenance, which prevents deterioration of performance even if there is a long time between electrode cleaning and replacement, make it extremely feasible for use at a wide variety of production sites.

Let IDEC help you solve your problems including improving productivity of the production site

There are many cases where static electricity, created for a wide variety of reasons, is one cause of reduced productivity. As IDEC can provide any number of various solutions to match the conditions of your production site, be sure to consult us in the case of static electricity or any other problems so we can help improve your productivity.