- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Flat LED Lighting

- Flat LED Lighting

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Sturdy Interlock Switches

- Sturdy Interlock Switches

- Smart Circuit Design

- Smart Circuit Design

- Smart Relays

- Smart Relays

- Solutions

- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Flat LED Lighting

- Flat LED Lighting

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Sturdy Interlock Switches

- Sturdy Interlock Switches

- Smart Circuit Design

- Smart Circuit Design

- Smart Relays

- Smart Relays

-

Solutions

- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Flat LED Lighting

- Flat LED Lighting

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Sturdy Interlock Switches

- Sturdy Interlock Switches

- Smart Circuit Design

- Smart Circuit Design

- Smart Relays

- Smart Relays

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Production Line Safety

- Production Line Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Smart Maintenance Safety

- Smart Maintenance Safety

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

- Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Production Line Safety

- Production Line Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Smart Maintenance Safety

- Smart Maintenance Safety

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

-

Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Production Line Safety

- Production Line Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Smart Maintenance Safety

- Smart Maintenance Safety

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

- Waterproof Switches

- Waterproof Switches

- Traceable Systems

- Traceable Systems

- Remote Monitoring

- Remote Monitoring

- Small Display Devices

- Small Display Devices

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Controllers

- Smart Controllers

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Affordable Robots

- Affordable Robots

- Smart Emergency Stop

- Smart Emergency Stop

- Smart Static Elimination

- Smart Static Elimination

- Solutions

- Waterproof Switches

- Waterproof Switches

- Traceable Systems

- Traceable Systems

- Remote Monitoring

- Remote Monitoring

- Small Display Devices

- Small Display Devices

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Controllers

- Smart Controllers

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Affordable Robots

- Affordable Robots

- Smart Emergency Stop

- Smart Emergency Stop

- Smart Static Elimination

- Smart Static Elimination

-

Solutions

- Waterproof Switches

- Waterproof Switches

- Traceable Systems

- Traceable Systems

- Remote Monitoring

- Remote Monitoring

- Small Display Devices

- Small Display Devices

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Controllers

- Smart Controllers

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Affordable Robots

- Affordable Robots

- Smart Emergency Stop

- Smart Emergency Stop

- Smart Static Elimination

- Smart Static Elimination

- Intrinsic Measures

- Intrinsic Measures

- Traceable Systems

- Traceable Systems

- Easy Traceability

- Easy Traceability

- Compact Equipment

- Compact Equipment

- Code Readers

- Code Readers

- Easy Switch Replacements

- Easy Switch Replacements

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Compact Safety Door Switches

- Compact Safety Door Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

- Solutions

- Intrinsic Measures

- Intrinsic Measures

- Traceable Systems

- Traceable Systems

- Easy Traceability

- Easy Traceability

- Compact Equipment

- Compact Equipment

- Code Readers

- Code Readers

- Easy Switch Replacements

- Easy Switch Replacements

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Compact Safety Door Switches

- Compact Safety Door Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

-

Solutions

- Intrinsic Measures

- Intrinsic Measures

- Traceable Systems

- Traceable Systems

- Easy Traceability

- Easy Traceability

- Compact Equipment

- Compact Equipment

- Code Readers

- Code Readers

- Easy Switch Replacements

- Easy Switch Replacements

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Compact Safety Door Switches

- Compact Safety Door Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

- Machine Tools

- Solutions

- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Flat LED Lighting

- Flat LED Lighting

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Sturdy Interlock Switches

- Sturdy Interlock Switches

- Smart Circuit Design

- Smart Circuit Design

- Smart Relays

- Smart Relays

-

Solutions

- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Flat LED Lighting

- Flat LED Lighting

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Sturdy Interlock Switches

- Sturdy Interlock Switches

- Smart Circuit Design

- Smart Circuit Design

- Smart Relays

- Smart Relays

-

Machine Tools

- Solutions

- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Flat LED Lighting

- Flat LED Lighting

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Sturdy Interlock Switches

- Sturdy Interlock Switches

- Smart Circuit Design

- Smart Circuit Design

- Smart Relays

- Smart Relays

-

Solutions

- Smart Safety Switches

- Smart Safety Switches

- Compact Equipment

- Compact Equipment

- Smart Machine Tools Design

- Smart Machine Tools Design

- Smart Machine Tools Maintenance

- Smart Machine Tools Maintenance

- Machine Surface Visibility

- Machine Surface Visibility

- Smart Switching Power Supply

- Smart Switching Power Supply

- Flat LED Lighting

- Flat LED Lighting

- Three-Position Enabling Switches

- Three-Position Enabling Switches

- Sturdy Interlock Switches

- Sturdy Interlock Switches

- Smart Circuit Design

- Smart Circuit Design

- Smart Relays

- Smart Relays

- Robotics

- Solutions

- Robot Safety Sensors

- Robot Safety Sensors

- Robot Safety Switches

- Robot Safety Switches

- Robot Warning System

- Robot Warning System

- Solutions

- Robotics

- Material Handling

- Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Production Line Safety

- Production Line Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Smart Maintenance Safety

- Smart Maintenance Safety

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

-

Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Production Line Safety

- Production Line Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Smart Maintenance Safety

- Smart Maintenance Safety

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

-

Material Handling

- Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Production Line Safety

- Production Line Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Smart Maintenance Safety

- Smart Maintenance Safety

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

-

Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Production Line Safety

- Production Line Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Smart Maintenance Safety

- Smart Maintenance Safety

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

- Food and Packaging

- Solutions

- Waterproof Switches

- Waterproof Switches

- Traceable Systems

- Traceable Systems

- Remote Monitoring

- Remote Monitoring

- Small Display Devices

- Small Display Devices

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Controllers

- Smart Controllers

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Affordable Robots

- Affordable Robots

- Smart Emergency Stop

- Smart Emergency Stop

- Smart Static Elimination

- Smart Static Elimination

-

Solutions

- Waterproof Switches

- Waterproof Switches

- Traceable Systems

- Traceable Systems

- Remote Monitoring

- Remote Monitoring

- Small Display Devices

- Small Display Devices

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Controllers

- Smart Controllers

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Affordable Robots

- Affordable Robots

- Smart Emergency Stop

- Smart Emergency Stop

- Smart Static Elimination

- Smart Static Elimination

-

Food and Packaging

- Solutions

- Waterproof Switches

- Waterproof Switches

- Traceable Systems

- Traceable Systems

- Remote Monitoring

- Remote Monitoring

- Small Display Devices

- Small Display Devices

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Controllers

- Smart Controllers

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Affordable Robots

- Affordable Robots

- Smart Emergency Stop

- Smart Emergency Stop

- Smart Static Elimination

- Smart Static Elimination

-

Solutions

- Waterproof Switches

- Waterproof Switches

- Traceable Systems

- Traceable Systems

- Remote Monitoring

- Remote Monitoring

- Small Display Devices

- Small Display Devices

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Controllers

- Smart Controllers

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Affordable Robots

- Affordable Robots

- Smart Emergency Stop

- Smart Emergency Stop

- Smart Static Elimination

- Smart Static Elimination

- Semiconductor

- Solutions

- Intrinsic Measures

- Intrinsic Measures

- Traceable Systems

- Traceable Systems

- Easy Traceability

- Easy Traceability

- Compact Equipment

- Compact Equipment

- Code Readers

- Code Readers

- Easy Switch Replacements

- Easy Switch Replacements

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Compact Safety Door Switches

- Compact Safety Door Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

-

Solutions

- Intrinsic Measures

- Intrinsic Measures

- Traceable Systems

- Traceable Systems

- Easy Traceability

- Easy Traceability

- Compact Equipment

- Compact Equipment

- Code Readers

- Code Readers

- Easy Switch Replacements

- Easy Switch Replacements

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Compact Safety Door Switches

- Compact Safety Door Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

-

Semiconductor

- Solutions

- Intrinsic Measures

- Intrinsic Measures

- Traceable Systems

- Traceable Systems

- Easy Traceability

- Easy Traceability

- Compact Equipment

- Compact Equipment

- Code Readers

- Code Readers

- Easy Switch Replacements

- Easy Switch Replacements

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Compact Safety Door Switches

- Compact Safety Door Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

-

Solutions

- Intrinsic Measures

- Intrinsic Measures

- Traceable Systems

- Traceable Systems

- Easy Traceability

- Easy Traceability

- Compact Equipment

- Compact Equipment

- Code Readers

- Code Readers

- Easy Switch Replacements

- Easy Switch Replacements

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Compact Safety Door Switches

- Compact Safety Door Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

- Special Vehicles

- Solutions

- Illuminated Switches

- Illuminated Switches

- Construction Site Safety

- Construction Site Safety

- LED Pilot Light

- LED Pilot Light

- Rugged Switch

- Rugged Switch

- Auto Machinery

- Auto Machinery

- No-Contact Controllers

- No-Contact Controllers

- Solutions

- Special Vehicles

- Automation of intralogistics

- Automation of intralogistics

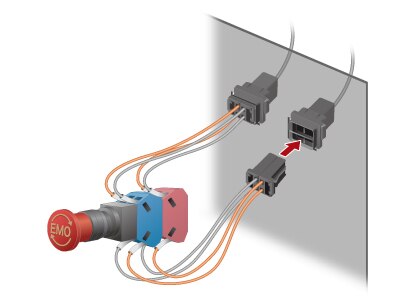

Easy Switch Replacement | EMEA

Switches can be replaced without using screwdrivers. Maintenance time is significantly reduced

Conventional code readers have limited options and high costs

At semiconductor manufacturing sites, preventing downtime is an important issue when maximizing production efficiency for ultimate throughput. However, whatever the countermeasure, the equipment must be temporarily stopped to replace parts during maintenance. For example, during wiring, screws are removed using a screwdriver, wiring is adjusted, and screws fixed using a screwdriver again. However, using a single screwdriver to remove so many screws takes time and effort. Furthermore, mechanical designers for semiconductor manufacturing equipment must satisfy the demand for downsizing, while at the same time securing enough space for workers needing to use a screwdriver.

Reduce downtime with quick and easy switch replacement

So what can be done to replace switches quickly and downsize equipment? IDEC has the solutions to the problem that design engineers may have. Our solution is to enable easy installation of switches by using a switch and harness so that wiring time is greatly reduced. By attaching a male connector on the cable side and female connector on the terminal block side which had been fixed using a screw, the cable can be easily and quickly removed even in tight spaces. This switch solution reduces time required for designing equipment and downtime when replacing switches.

IDEC switches are an ideal solution for your application needs

IDEC understands the requirement of semiconductor manufacturing devices ensuring our customers total support from drawing switch parts, quality control, to delivery. We can customize products to meet customer demands such as cable length adjustment and switches with connectors. We can also support customers regarding system solutions such as using connectors for wiring switches and single board mounting. Contact IDEC if you have any concerns about switches.

Reduce total cost with high-performance compact code reader

In conventional designs, code readers installed on load ports had limited installation flexibility. In addition to having to purchase additional parts used to adjust the reading angle, it also took a lot of time to set it up at the correct angle. There were also many semiconductor manufacturing equipment load port designers who thought that it was important to reduce the total cost including the code reader.

In response to this, IDEC introduced the WB2F 2D code scanner capable of reliably reading codes at an angle. Just 24mm x 40 mm x 32 mm in size, the compact WB2F is equipped with a high resolution 1.2 megapixel CMOS image sensor can read small symbols over a wide area. It can be easily integrated into small devices.

In addition to the auto-tuning function that reduces overall adjustment time, this model is also equipped with an image storage function that reduces the amount of work required when there is a reading error. This allows excellent traceability while keeping costs low.

Ideal for semiconductor manufacturing applications in addition to load ports

The WB2F 2D code scanner is capable of reading codes even from distances up to 150 mm. It is also compatible with various types of barcode and 2D codes.

Therefore, it is possible to read codes installed in various locations and can be used in a wide range of applications such as with FOUP enclosures holding 300 mm wafers, cassettes holding 200 mm wafers, and wafer frames that prevent damage.