- Interrupteurs de sécurité intelligents

- Interrupteurs de sécurité intelligents

- Équipements compacts

- Équipements compacts

- Conception de machines-outils intelligentes

- Conception de machines-outils intelligentes

- Maintenance intelligente des machines-outils

- Maintenance intelligente des machines-outils

- Visibilité des surfaces usinées

- Visibilité des surfaces usinées

- Alimentation à découpage intelligente

- Alimentation à découpage intelligente

- Éclairage plat à LED

- Éclairage plat à LED

- Positionnement des interrupteurs d’assentiment

- Positionnement des interrupteurs d’assentiment

- Interrupteurs de verrouillage robustes

- Interrupteurs de verrouillage robustes

- Relais intelligents

- Relais intelligents

- Smart Relays

- Smart Relays

- Solutions

- Interrupteurs de sécurité intelligents

- Interrupteurs de sécurité intelligents

- Équipements compacts

- Équipements compacts

- Conception de machines-outils intelligentes

- Conception de machines-outils intelligentes

- Maintenance intelligente des machines-outils

- Maintenance intelligente des machines-outils

- Visibilité des surfaces usinées

- Visibilité des surfaces usinées

- Alimentation à découpage intelligente

- Alimentation à découpage intelligente

- Éclairage plat à LED

- Éclairage plat à LED

- Positionnement des interrupteurs d’assentiment

- Positionnement des interrupteurs d’assentiment

- Interrupteurs de verrouillage robustes

- Interrupteurs de verrouillage robustes

- Relais intelligents

- Relais intelligents

- Smart Relays

- Smart Relays

-

Solutions

- Interrupteurs de sécurité intelligents

- Interrupteurs de sécurité intelligents

- Équipements compacts

- Équipements compacts

- Conception de machines-outils intelligentes

- Conception de machines-outils intelligentes

- Maintenance intelligente des machines-outils

- Maintenance intelligente des machines-outils

- Visibilité des surfaces usinées

- Visibilité des surfaces usinées

- Alimentation à découpage intelligente

- Alimentation à découpage intelligente

- Éclairage plat à LED

- Éclairage plat à LED

- Positionnement des interrupteurs d’assentiment

- Positionnement des interrupteurs d’assentiment

- Interrupteurs de verrouillage robustes

- Interrupteurs de verrouillage robustes

- Relais intelligents

- Relais intelligents

- Smart Relays

- Smart Relays

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Production Line Safety

- Production Line Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Smart Maintenance Safety

- Smart Maintenance Safety

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

- Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Production Line Safety

- Production Line Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Smart Maintenance Safety

- Smart Maintenance Safety

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

-

Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Production Line Safety

- Production Line Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Smart Maintenance Safety

- Smart Maintenance Safety

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

- Waterproof Switches

- Waterproof Switches

- Traceable Systems

- Traceable Systems

- Remote Monitoring

- Remote Monitoring

- Small Display Devices

- Small Display Devices

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Controllers

- Smart Controllers

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Affordable Robots

- Affordable Robots

- Smart Emergency Stop

- Smart Emergency Stop

- Smart Static Elimination

- Smart Static Elimination

- Solutions

- Waterproof Switches

- Waterproof Switches

- Traceable Systems

- Traceable Systems

- Remote Monitoring

- Remote Monitoring

- Small Display Devices

- Small Display Devices

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Controllers

- Smart Controllers

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Affordable Robots

- Affordable Robots

- Smart Emergency Stop

- Smart Emergency Stop

- Smart Static Elimination

- Smart Static Elimination

-

Solutions

- Waterproof Switches

- Waterproof Switches

- Traceable Systems

- Traceable Systems

- Remote Monitoring

- Remote Monitoring

- Small Display Devices

- Small Display Devices

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Controllers

- Smart Controllers

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Affordable Robots

- Affordable Robots

- Smart Emergency Stop

- Smart Emergency Stop

- Smart Static Elimination

- Smart Static Elimination

- Intrinsic Measures

- Intrinsic Measures

- Traceable Systems

- Traceable Systems

- Easy Traceability

- Easy Traceability

- Compact Equipment

- Compact Equipment

- Code Readers

- Code Readers

- Easy Switch Replacements

- Easy Switch Replacements

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Compact Safety Door Switches

- Compact Safety Door Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

- Solutions

- Intrinsic Measures

- Intrinsic Measures

- Traceable Systems

- Traceable Systems

- Easy Traceability

- Easy Traceability

- Compact Equipment

- Compact Equipment

- Code Readers

- Code Readers

- Easy Switch Replacements

- Easy Switch Replacements

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Compact Safety Door Switches

- Compact Safety Door Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

-

Solutions

- Intrinsic Measures

- Intrinsic Measures

- Traceable Systems

- Traceable Systems

- Easy Traceability

- Easy Traceability

- Compact Equipment

- Compact Equipment

- Code Readers

- Code Readers

- Easy Switch Replacements

- Easy Switch Replacements

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Compact Safety Door Switches

- Compact Safety Door Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

- Machines-outils

- Solutions

- Interrupteurs de sécurité intelligents

- Interrupteurs de sécurité intelligents

- Équipements compacts

- Équipements compacts

- Conception de machines-outils intelligentes

- Conception de machines-outils intelligentes

- Maintenance intelligente des machines-outils

- Maintenance intelligente des machines-outils

- Visibilité des surfaces usinées

- Visibilité des surfaces usinées

- Alimentation à découpage intelligente

- Alimentation à découpage intelligente

- Éclairage plat à LED

- Éclairage plat à LED

- Positionnement des interrupteurs d’assentiment

- Positionnement des interrupteurs d’assentiment

- Interrupteurs de verrouillage robustes

- Interrupteurs de verrouillage robustes

- Relais intelligents

- Relais intelligents

- Smart Relays

- Smart Relays

-

Solutions

- Interrupteurs de sécurité intelligents

- Interrupteurs de sécurité intelligents

- Équipements compacts

- Équipements compacts

- Conception de machines-outils intelligentes

- Conception de machines-outils intelligentes

- Maintenance intelligente des machines-outils

- Maintenance intelligente des machines-outils

- Visibilité des surfaces usinées

- Visibilité des surfaces usinées

- Alimentation à découpage intelligente

- Alimentation à découpage intelligente

- Éclairage plat à LED

- Éclairage plat à LED

- Positionnement des interrupteurs d’assentiment

- Positionnement des interrupteurs d’assentiment

- Interrupteurs de verrouillage robustes

- Interrupteurs de verrouillage robustes

- Relais intelligents

- Relais intelligents

- Smart Relays

- Smart Relays

-

Machines-outils

- Solutions

- Interrupteurs de sécurité intelligents

- Interrupteurs de sécurité intelligents

- Équipements compacts

- Équipements compacts

- Conception de machines-outils intelligentes

- Conception de machines-outils intelligentes

- Maintenance intelligente des machines-outils

- Maintenance intelligente des machines-outils

- Visibilité des surfaces usinées

- Visibilité des surfaces usinées

- Alimentation à découpage intelligente

- Alimentation à découpage intelligente

- Éclairage plat à LED

- Éclairage plat à LED

- Positionnement des interrupteurs d’assentiment

- Positionnement des interrupteurs d’assentiment

- Interrupteurs de verrouillage robustes

- Interrupteurs de verrouillage robustes

- Relais intelligents

- Relais intelligents

- Smart Relays

- Smart Relays

-

Solutions

- Interrupteurs de sécurité intelligents

- Interrupteurs de sécurité intelligents

- Équipements compacts

- Équipements compacts

- Conception de machines-outils intelligentes

- Conception de machines-outils intelligentes

- Maintenance intelligente des machines-outils

- Maintenance intelligente des machines-outils

- Visibilité des surfaces usinées

- Visibilité des surfaces usinées

- Alimentation à découpage intelligente

- Alimentation à découpage intelligente

- Éclairage plat à LED

- Éclairage plat à LED

- Positionnement des interrupteurs d’assentiment

- Positionnement des interrupteurs d’assentiment

- Interrupteurs de verrouillage robustes

- Interrupteurs de verrouillage robustes

- Relais intelligents

- Relais intelligents

- Smart Relays

- Smart Relays

- Robotique

- Solutions

- Robot Safety Sensors

- Robot Safety Sensors

- Robot Safety Switches

- Robot Safety Switches

- Robot Warning System

- Robot Warning System

- Solutions

- Robotique

- Engins de levage

- Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Production Line Safety

- Production Line Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Smart Maintenance Safety

- Smart Maintenance Safety

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

-

Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Production Line Safety

- Production Line Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Smart Maintenance Safety

- Smart Maintenance Safety

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

-

Engins de levage

- Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Production Line Safety

- Production Line Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Smart Maintenance Safety

- Smart Maintenance Safety

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

-

Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Production Line Safety

- Production Line Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Smart Maintenance Safety

- Smart Maintenance Safety

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

- Agro-alimentaire et conditionnement

- Solutions

- Waterproof Switches

- Waterproof Switches

- Traceable Systems

- Traceable Systems

- Remote Monitoring

- Remote Monitoring

- Small Display Devices

- Small Display Devices

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Controllers

- Smart Controllers

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Affordable Robots

- Affordable Robots

- Smart Emergency Stop

- Smart Emergency Stop

- Smart Static Elimination

- Smart Static Elimination

-

Solutions

- Waterproof Switches

- Waterproof Switches

- Traceable Systems

- Traceable Systems

- Remote Monitoring

- Remote Monitoring

- Small Display Devices

- Small Display Devices

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Controllers

- Smart Controllers

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Affordable Robots

- Affordable Robots

- Smart Emergency Stop

- Smart Emergency Stop

- Smart Static Elimination

- Smart Static Elimination

-

Agro-alimentaire et conditionnement

- Solutions

- Waterproof Switches

- Waterproof Switches

- Traceable Systems

- Traceable Systems

- Remote Monitoring

- Remote Monitoring

- Small Display Devices

- Small Display Devices

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Controllers

- Smart Controllers

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Affordable Robots

- Affordable Robots

- Smart Emergency Stop

- Smart Emergency Stop

- Smart Static Elimination

- Smart Static Elimination

-

Solutions

- Waterproof Switches

- Waterproof Switches

- Traceable Systems

- Traceable Systems

- Remote Monitoring

- Remote Monitoring

- Small Display Devices

- Small Display Devices

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Controllers

- Smart Controllers

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Affordable Robots

- Affordable Robots

- Smart Emergency Stop

- Smart Emergency Stop

- Smart Static Elimination

- Smart Static Elimination

- Semi-conducteurs

- Solutions

- Intrinsic Measures

- Intrinsic Measures

- Traceable Systems

- Traceable Systems

- Easy Traceability

- Easy Traceability

- Compact Equipment

- Compact Equipment

- Code Readers

- Code Readers

- Easy Switch Replacements

- Easy Switch Replacements

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Compact Safety Door Switches

- Compact Safety Door Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

-

Solutions

- Intrinsic Measures

- Intrinsic Measures

- Traceable Systems

- Traceable Systems

- Easy Traceability

- Easy Traceability

- Compact Equipment

- Compact Equipment

- Code Readers

- Code Readers

- Easy Switch Replacements

- Easy Switch Replacements

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Compact Safety Door Switches

- Compact Safety Door Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

-

Semi-conducteurs

- Solutions

- Intrinsic Measures

- Intrinsic Measures

- Traceable Systems

- Traceable Systems

- Easy Traceability

- Easy Traceability

- Compact Equipment

- Compact Equipment

- Code Readers

- Code Readers

- Easy Switch Replacements

- Easy Switch Replacements

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Compact Safety Door Switches

- Compact Safety Door Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

-

Solutions

- Intrinsic Measures

- Intrinsic Measures

- Traceable Systems

- Traceable Systems

- Easy Traceability

- Easy Traceability

- Compact Equipment

- Compact Equipment

- Code Readers

- Code Readers

- Easy Switch Replacements

- Easy Switch Replacements

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Compact Safety Door Switches

- Compact Safety Door Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

- Véhicules spéciaux

- Solutions

- Illuminated Switches

- Illuminated Switches

- Construction Site Safety

- Construction Site Safety

- LED Pilot Light

- LED Pilot Light

- Rugged Switch

- Rugged Switch

- Auto Machinery

- Auto Machinery

- No-Contact Controllers

- No-Contact Controllers

- Solutions

- Véhicules spéciaux

- Automation of intralogistics

- Automation of intralogistics

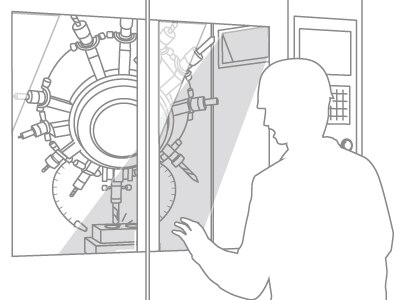

Visibilité des surfaces usinées | EMEA

Utiliser une LED plate pour rendre visibles les marques de broutage sur la surface usinée à un stade précoce

Delay in finding chatter marks impacted the next processes

A machine designer at machining center at a machine tool manufacturer who takes pride in its high precision mentioned that lately, more and more sales people from the company and also the support departments ask him about the rigidity or reliability of products. According to them, chatter marks become visible after only a few operating hours have passed, and more users send them complaints or demand to find the cause of the problem.

As he investigated the cause, he found that the glares from LED lighting inside the machine tool tend to be seen as chatter marks while visually checking the machine operation. He thought that users probably missed chatter marks because of such tendency, and because they missed and the chatter marks were left untreated, maintenance was delayed and the situation worsened. For this problem, IDEC provided a solution to enable anybody identify chatter marks at a glance. What was used to solve the situation?

LED lighting inside machine tool allows for clear identification of chatter marks

Standards such as ISO23215, JIS B6031, and EN 1837 stipulate that illumination inside machine tools must have 500 lux luminance. We analyzed how the light inside the panel shone. The conventional illumination cleared the requirement of 500 lux or higher luminance. However, each of lined-up LED elements emitted light individually, and the light shone unevenly, creating uneven patterns. It was found that this made it difficult to identify chatter marks.

IDEC proposed the One-Core LED LF1D−C Series to the customer. LF1D−C is flat illumination capable of emitting light to the surface evenly, which is perfect for illumination inside a panel. Using LF1D−C to shine light on a piece of work made it possible to check whether chatter marks have been generated or not easily, at a glance. The customer was surprised and thanked, saying “it is great that the product has light distribution capability to light machined surfaces so nicely. This must be useful for visual checking. We would definitely like to adopt this product as illumination inside machine tools for other machining centers.”

Une gamme variée de produits de commande pour résoudre les problèmes sur les sites de production

IDEC ne dispose pas seulement de l’éclairage à LED à l’intérieur des machines-outils, mais aussi de produits de commande et de sécurité tels que les API, IHM, boutons-poussoirs, voyants lumineux, relais, interrupteurs de verrouillage, interrupteurs d’arrêt d’urgence, interrupteurs d’assentiment, scanners laser de sécurité et commandes de sécurité. IDEC a la confiance et l’expérience en matière de sécurité, avec le plus grand nombre d’évaluateurs de sécurité du secteur. Nous pouvons vous donner des conseils sur les solutions de sécurité globale sur les sites de fabrication, et pas seulement sur les produits de sécurité. N'hésitez pas à consulter IDEC si vous rencontrez des problèmes sur les sites de production.