- Interrupteurs de sécurité intelligents

- Interrupteurs de sécurité intelligents

- Équipements compacts

- Équipements compacts

- Conception de machines-outils intelligentes

- Conception de machines-outils intelligentes

- Maintenance intelligente des machines-outils

- Maintenance intelligente des machines-outils

- Visibilité des surfaces usinées

- Visibilité des surfaces usinées

- Alimentation à découpage intelligente

- Alimentation à découpage intelligente

- Éclairage plat à LED

- Éclairage plat à LED

- Positionnement des interrupteurs d’assentiment

- Positionnement des interrupteurs d’assentiment

- Interrupteurs de verrouillage robustes

- Interrupteurs de verrouillage robustes

- Relais intelligents

- Relais intelligents

- Smart Relays

- Smart Relays

- Solutions

- Interrupteurs de sécurité intelligents

- Interrupteurs de sécurité intelligents

- Équipements compacts

- Équipements compacts

- Conception de machines-outils intelligentes

- Conception de machines-outils intelligentes

- Maintenance intelligente des machines-outils

- Maintenance intelligente des machines-outils

- Visibilité des surfaces usinées

- Visibilité des surfaces usinées

- Alimentation à découpage intelligente

- Alimentation à découpage intelligente

- Éclairage plat à LED

- Éclairage plat à LED

- Positionnement des interrupteurs d’assentiment

- Positionnement des interrupteurs d’assentiment

- Interrupteurs de verrouillage robustes

- Interrupteurs de verrouillage robustes

- Relais intelligents

- Relais intelligents

- Smart Relays

- Smart Relays

-

Solutions

- Interrupteurs de sécurité intelligents

- Interrupteurs de sécurité intelligents

- Équipements compacts

- Équipements compacts

- Conception de machines-outils intelligentes

- Conception de machines-outils intelligentes

- Maintenance intelligente des machines-outils

- Maintenance intelligente des machines-outils

- Visibilité des surfaces usinées

- Visibilité des surfaces usinées

- Alimentation à découpage intelligente

- Alimentation à découpage intelligente

- Éclairage plat à LED

- Éclairage plat à LED

- Positionnement des interrupteurs d’assentiment

- Positionnement des interrupteurs d’assentiment

- Interrupteurs de verrouillage robustes

- Interrupteurs de verrouillage robustes

- Relais intelligents

- Relais intelligents

- Smart Relays

- Smart Relays

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Production Line Safety

- Production Line Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Smart Maintenance Safety

- Smart Maintenance Safety

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

- Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Production Line Safety

- Production Line Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Smart Maintenance Safety

- Smart Maintenance Safety

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

-

Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Production Line Safety

- Production Line Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Smart Maintenance Safety

- Smart Maintenance Safety

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

- Waterproof Switches

- Waterproof Switches

- Traceable Systems

- Traceable Systems

- Remote Monitoring

- Remote Monitoring

- Small Display Devices

- Small Display Devices

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Controllers

- Smart Controllers

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Affordable Robots

- Affordable Robots

- Smart Emergency Stop

- Smart Emergency Stop

- Smart Static Elimination

- Smart Static Elimination

- Solutions

- Waterproof Switches

- Waterproof Switches

- Traceable Systems

- Traceable Systems

- Remote Monitoring

- Remote Monitoring

- Small Display Devices

- Small Display Devices

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Controllers

- Smart Controllers

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Affordable Robots

- Affordable Robots

- Smart Emergency Stop

- Smart Emergency Stop

- Smart Static Elimination

- Smart Static Elimination

-

Solutions

- Waterproof Switches

- Waterproof Switches

- Traceable Systems

- Traceable Systems

- Remote Monitoring

- Remote Monitoring

- Small Display Devices

- Small Display Devices

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Controllers

- Smart Controllers

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Affordable Robots

- Affordable Robots

- Smart Emergency Stop

- Smart Emergency Stop

- Smart Static Elimination

- Smart Static Elimination

- Intrinsic Measures

- Intrinsic Measures

- Traceable Systems

- Traceable Systems

- Easy Traceability

- Easy Traceability

- Compact Equipment

- Compact Equipment

- Code Readers

- Code Readers

- Easy Switch Replacements

- Easy Switch Replacements

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Compact Safety Door Switches

- Compact Safety Door Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

- Solutions

- Intrinsic Measures

- Intrinsic Measures

- Traceable Systems

- Traceable Systems

- Easy Traceability

- Easy Traceability

- Compact Equipment

- Compact Equipment

- Code Readers

- Code Readers

- Easy Switch Replacements

- Easy Switch Replacements

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Compact Safety Door Switches

- Compact Safety Door Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

-

Solutions

- Intrinsic Measures

- Intrinsic Measures

- Traceable Systems

- Traceable Systems

- Easy Traceability

- Easy Traceability

- Compact Equipment

- Compact Equipment

- Code Readers

- Code Readers

- Easy Switch Replacements

- Easy Switch Replacements

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Compact Safety Door Switches

- Compact Safety Door Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

- Machines-outils

- Solutions

- Interrupteurs de sécurité intelligents

- Interrupteurs de sécurité intelligents

- Équipements compacts

- Équipements compacts

- Conception de machines-outils intelligentes

- Conception de machines-outils intelligentes

- Maintenance intelligente des machines-outils

- Maintenance intelligente des machines-outils

- Visibilité des surfaces usinées

- Visibilité des surfaces usinées

- Alimentation à découpage intelligente

- Alimentation à découpage intelligente

- Éclairage plat à LED

- Éclairage plat à LED

- Positionnement des interrupteurs d’assentiment

- Positionnement des interrupteurs d’assentiment

- Interrupteurs de verrouillage robustes

- Interrupteurs de verrouillage robustes

- Relais intelligents

- Relais intelligents

- Smart Relays

- Smart Relays

-

Solutions

- Interrupteurs de sécurité intelligents

- Interrupteurs de sécurité intelligents

- Équipements compacts

- Équipements compacts

- Conception de machines-outils intelligentes

- Conception de machines-outils intelligentes

- Maintenance intelligente des machines-outils

- Maintenance intelligente des machines-outils

- Visibilité des surfaces usinées

- Visibilité des surfaces usinées

- Alimentation à découpage intelligente

- Alimentation à découpage intelligente

- Éclairage plat à LED

- Éclairage plat à LED

- Positionnement des interrupteurs d’assentiment

- Positionnement des interrupteurs d’assentiment

- Interrupteurs de verrouillage robustes

- Interrupteurs de verrouillage robustes

- Relais intelligents

- Relais intelligents

- Smart Relays

- Smart Relays

-

Machines-outils

- Solutions

- Interrupteurs de sécurité intelligents

- Interrupteurs de sécurité intelligents

- Équipements compacts

- Équipements compacts

- Conception de machines-outils intelligentes

- Conception de machines-outils intelligentes

- Maintenance intelligente des machines-outils

- Maintenance intelligente des machines-outils

- Visibilité des surfaces usinées

- Visibilité des surfaces usinées

- Alimentation à découpage intelligente

- Alimentation à découpage intelligente

- Éclairage plat à LED

- Éclairage plat à LED

- Positionnement des interrupteurs d’assentiment

- Positionnement des interrupteurs d’assentiment

- Interrupteurs de verrouillage robustes

- Interrupteurs de verrouillage robustes

- Relais intelligents

- Relais intelligents

- Smart Relays

- Smart Relays

-

Solutions

- Interrupteurs de sécurité intelligents

- Interrupteurs de sécurité intelligents

- Équipements compacts

- Équipements compacts

- Conception de machines-outils intelligentes

- Conception de machines-outils intelligentes

- Maintenance intelligente des machines-outils

- Maintenance intelligente des machines-outils

- Visibilité des surfaces usinées

- Visibilité des surfaces usinées

- Alimentation à découpage intelligente

- Alimentation à découpage intelligente

- Éclairage plat à LED

- Éclairage plat à LED

- Positionnement des interrupteurs d’assentiment

- Positionnement des interrupteurs d’assentiment

- Interrupteurs de verrouillage robustes

- Interrupteurs de verrouillage robustes

- Relais intelligents

- Relais intelligents

- Smart Relays

- Smart Relays

- Robotique

- Solutions

- Robot Safety Sensors

- Robot Safety Sensors

- Robot Safety Switches

- Robot Safety Switches

- Robot Warning System

- Robot Warning System

- Solutions

- Robotique

- Engins de levage

- Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Production Line Safety

- Production Line Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Smart Maintenance Safety

- Smart Maintenance Safety

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

-

Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Production Line Safety

- Production Line Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Smart Maintenance Safety

- Smart Maintenance Safety

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

-

Engins de levage

- Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Production Line Safety

- Production Line Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Smart Maintenance Safety

- Smart Maintenance Safety

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

-

Solutions

- Smart Blind Spot Safety

- Smart Blind Spot Safety

- Smart Overhead Transfer Safety

- Smart Overhead Transfer Safety

- Production Line Safety

- Production Line Safety

- Smart Palletizing Robot Safety

- Smart Palletizing Robot Safety

- Smart Protective Fence Safety

- Smart Protective Fence Safety

- Smart Safety Switches

- Smart Safety Switches

- Automated Storage Switches

- Automated Storage Switches

- Smart Maintenance Safety

- Smart Maintenance Safety

- Retrieving Area Safety

- Retrieving Area Safety

- Smart Screen Updates

- Smart Screen Updates

- Simple Safety Measure for Movable Robots

- Simple Safety Measure for Movable Robots

- Wearable Code Reader

- Wearable Code Reader

- Agro-alimentaire et conditionnement

- Solutions

- Waterproof Switches

- Waterproof Switches

- Traceable Systems

- Traceable Systems

- Remote Monitoring

- Remote Monitoring

- Small Display Devices

- Small Display Devices

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Controllers

- Smart Controllers

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Affordable Robots

- Affordable Robots

- Smart Emergency Stop

- Smart Emergency Stop

- Smart Static Elimination

- Smart Static Elimination

-

Solutions

- Waterproof Switches

- Waterproof Switches

- Traceable Systems

- Traceable Systems

- Remote Monitoring

- Remote Monitoring

- Small Display Devices

- Small Display Devices

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Controllers

- Smart Controllers

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Affordable Robots

- Affordable Robots

- Smart Emergency Stop

- Smart Emergency Stop

- Smart Static Elimination

- Smart Static Elimination

-

Agro-alimentaire et conditionnement

- Solutions

- Waterproof Switches

- Waterproof Switches

- Traceable Systems

- Traceable Systems

- Remote Monitoring

- Remote Monitoring

- Small Display Devices

- Small Display Devices

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Controllers

- Smart Controllers

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Affordable Robots

- Affordable Robots

- Smart Emergency Stop

- Smart Emergency Stop

- Smart Static Elimination

- Smart Static Elimination

-

Solutions

- Waterproof Switches

- Waterproof Switches

- Traceable Systems

- Traceable Systems

- Remote Monitoring

- Remote Monitoring

- Small Display Devices

- Small Display Devices

- Low Temperature Equipment

- Low Temperature Equipment

- Smart Controllers

- Smart Controllers

- Smart Control Boxes

- Smart Control Boxes

- Smart Interface and Controls

- Smart Interface and Controls

- Collaborative Robots

- Collaborative Robots

- Food Processing Control Panels

- Food Processing Control Panels

- Affordable Robots

- Affordable Robots

- Smart Emergency Stop

- Smart Emergency Stop

- Smart Static Elimination

- Smart Static Elimination

- Semi-conducteurs

- Solutions

- Intrinsic Measures

- Intrinsic Measures

- Traceable Systems

- Traceable Systems

- Easy Traceability

- Easy Traceability

- Compact Equipment

- Compact Equipment

- Code Readers

- Code Readers

- Easy Switch Replacements

- Easy Switch Replacements

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Compact Safety Door Switches

- Compact Safety Door Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

-

Solutions

- Intrinsic Measures

- Intrinsic Measures

- Traceable Systems

- Traceable Systems

- Easy Traceability

- Easy Traceability

- Compact Equipment

- Compact Equipment

- Code Readers

- Code Readers

- Easy Switch Replacements

- Easy Switch Replacements

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Compact Safety Door Switches

- Compact Safety Door Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

-

Semi-conducteurs

- Solutions

- Intrinsic Measures

- Intrinsic Measures

- Traceable Systems

- Traceable Systems

- Easy Traceability

- Easy Traceability

- Compact Equipment

- Compact Equipment

- Code Readers

- Code Readers

- Easy Switch Replacements

- Easy Switch Replacements

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Compact Safety Door Switches

- Compact Safety Door Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

-

Solutions

- Intrinsic Measures

- Intrinsic Measures

- Traceable Systems

- Traceable Systems

- Easy Traceability

- Easy Traceability

- Compact Equipment

- Compact Equipment

- Code Readers

- Code Readers

- Easy Switch Replacements

- Easy Switch Replacements

- Smart Lighting

- Smart Lighting

- Photoelectric Sensors

- Photoelectric Sensors

- U.S. Compliant Switchboards

- U.S. Compliant Switchboards

- Smart EMO Switches

- Smart EMO Switches

- Compact Safety Door Switches

- Compact Safety Door Switches

- Flush Switches

- Flush Switches

- Smart Static Elimination

- Smart Static Elimination

- Véhicules spéciaux

- Solutions

- Illuminated Switches

- Illuminated Switches

- Construction Site Safety

- Construction Site Safety

- LED Pilot Light

- LED Pilot Light

- Rugged Switch

- Rugged Switch

- Auto Machinery

- Auto Machinery

- No-Contact Controllers

- No-Contact Controllers

- Solutions

- Véhicules spéciaux

- Automation of intralogistics

- Automation of intralogistics

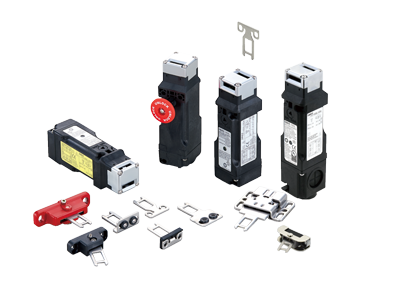

Sturdy Interlock Switches | EMEA

Reduce down time and cost with sturdy interlock switches

The challenge: ensure both safety and productivity

I want to improve the decrease in production efficiency due to downtime.

A person in charge of machine design at a machine tool manufacturer, who is in charge of equipment operation and safety. Under the theme of "coexistence of humans and machines," we are taking on challenges every day with the aim of achieving both safety and production efficiency.

While designing the process of setting tools and materials by humans and then processing by machines, I always wanted to solve "unintentional downtime" due to a failure of the safety switch attached to the door. .. If the solenoid unit of the safety switch is connected to the controller via a relay, the door will be locked in the unlikely event that the relay fails. Whenever this situation occurred, the person in charge felt that it was a waste to have downtime just because of a relay failure.

For such a person in charge, IDEC used something to solve the problem of "unintentional downtime" due to the failure of the safety relay. What did you do?

Reduce the cause of failure with a safety switch that eliminates the need for relays

Relays themselves are consumables and deteriorate over time, so you must assume a failure in the first place. In addition, when inspecting equipment, it takes time and effort to check the degree of deterioration and replace it. If left unattended, a relay failure can result in unintended downtime.

On the other hand, IDEC is a spring lock type safety switch with solenoid "HS5L type", "HS1L type (lock strength 3,000N)" and "HS1T type (lock strength 5,000N)" that can be used without using a relay that causes a failure. I proposed. Since the rated current value of the solenoid unit is 200mA, if the output specification of the controller is 200mA, power can be supplied directly and no relay is required.

The person in charge was very pleased to be able to reduce the parts that cause failures and reduce the "unintended downtime" that was originally planned.

A diverse lineup of safety equipment that realizes safety at production sites

IDEC has the largest number of safety assessors in the industry, in addition to safety devices such as safety switches, emergency stop switches, enable switches, safety laser scanners, and safety controllers, and has a proven track record in safety. Not only safety equipment but also general safety solutions at the manufacturing site can be consulted. If you have any problems with safety measures, please feel free to contact IDEC.